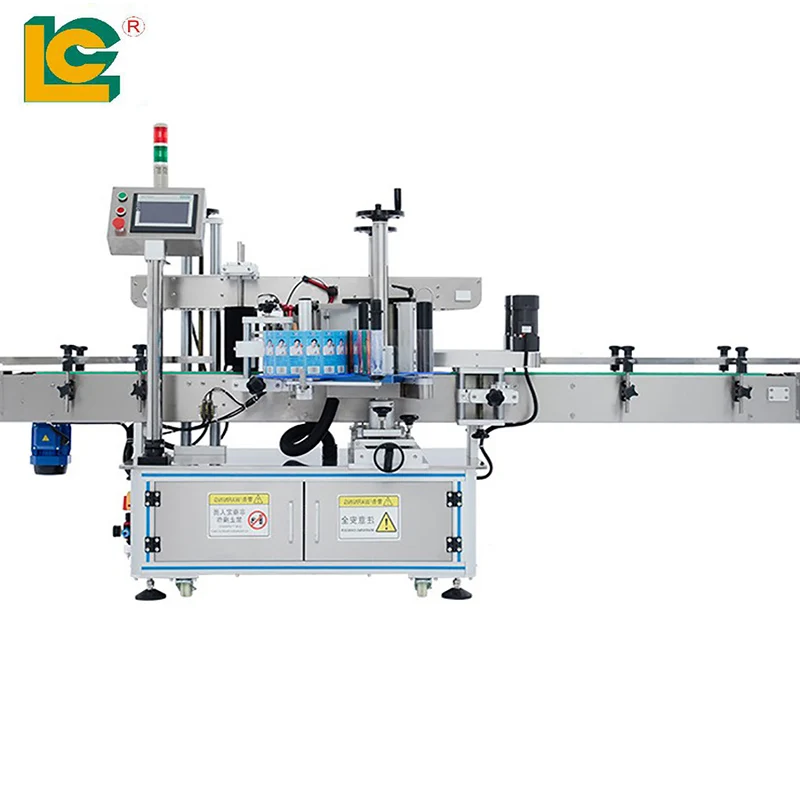

LC 34 Years of Manufacturing Laundry Detergent Bottle Automatic Double-sided Labeling Daily Chemical Barrel Labeling Machine

Model : LC-LM-712-00

Brand Name : LC

Origin : China

Quantity : 1 unit of equipment

Brand Name : LC

Origin : China

Quantity : 1 unit of equipment

Product Description

Fully automatic multi-function side labeling machine

Basic use It is suitable for single-side and double-side labeling of flat bottles, round bottles and square bottles, such as shampoo flat bottles, lubricating oil flat bottles, hand sanitizer round bottles and other double-side labeling, both sides of the same labeling, double labeling improves production efficiency, and is widely used in daily chemical, cosmetics, petrochemical, pharmaceutical and other industries.

Scope of application *Applicable labels: self-adhesive label, non-adhesive film, electronic supervision code, bar code, etc. *Applicable products: Products requiring labels on the side plane, side large radian surface, and circular surface. *Application industry: Widely used in cosmetics, daily chemical, electronics, medicine, hardware, plastic and other industries. *Application examples: shampoo flat bottle labeling, lubricating oil flat bottle labeling, shampoo round bottle labeling, beverage bottle labeling, etc.

Specification

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

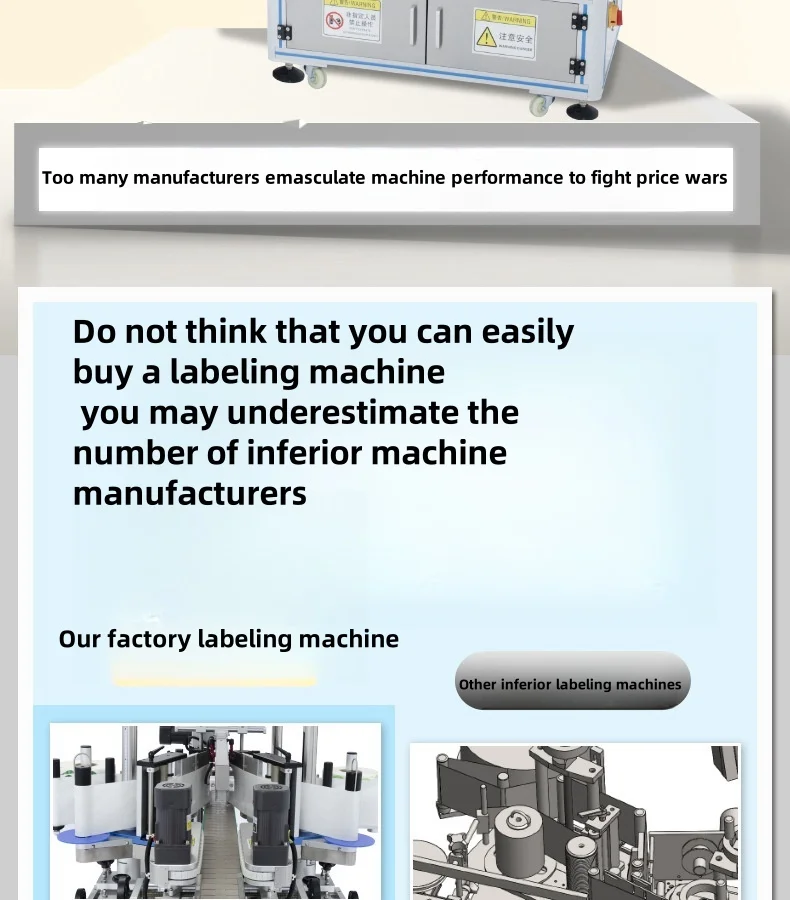

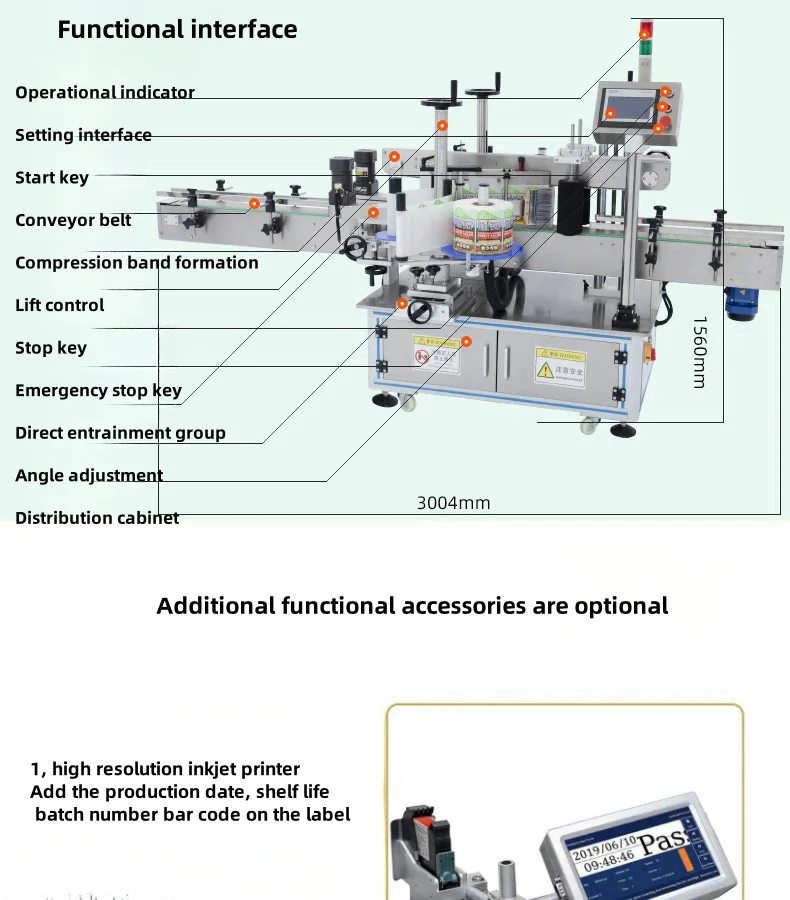

Automatic double side labeling machine features:

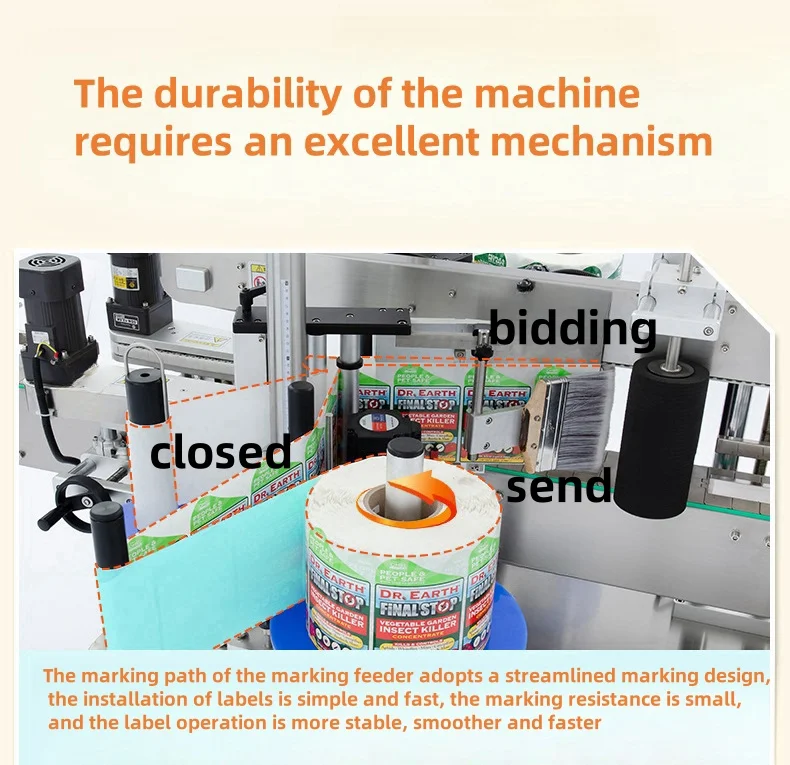

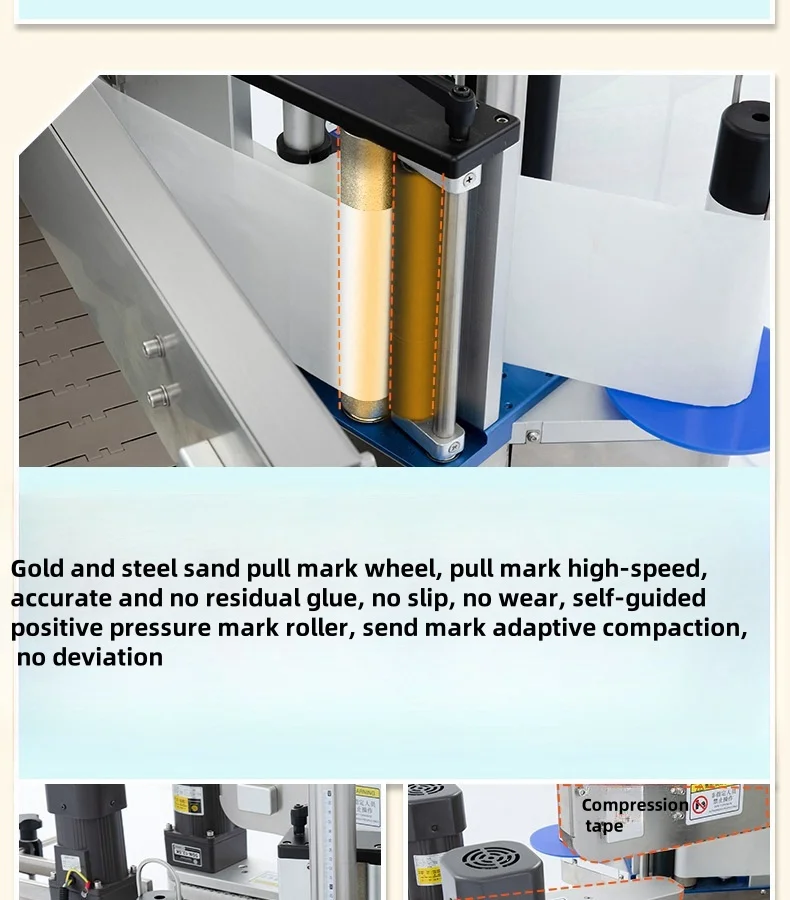

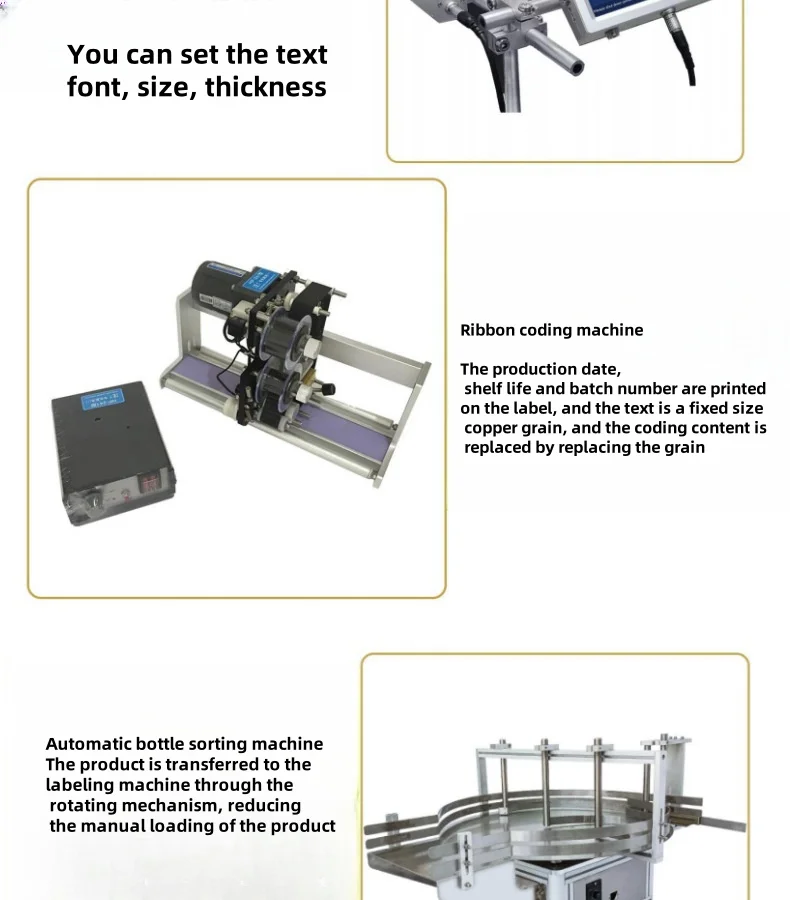

1. Powerful, one machine can achieve a variety of products single-sided/double-sided labeling; 2. The two-sided rigid plastic synchronous guide chain is used to automatically ensure that the bottle is neutral, and the requirements for workers to place bottles and the assembly line docking into the bottle are low, greatly reducing the difficulty of workers' operation or assembly line docking, which can be single production or assembly line production; 3. The configuration of the elastic top pressing mechanism ensures the smooth transmission of the product and effectively eliminates the error of the bottle height; 4. Automatic bottle splitting mechanism is configured to automatically separate the spacing before the guide bottle to ensure the stability of the subsequent guide bottle, conveying and labeling; 5. Configure two repeat marking mechanisms to ensure the labeling accuracy for the first time, and double extrusion marking to effectively eliminate bubbles and ensure that the label head and tail are tight; 6. Intelligent control, high stability, automatic photoelectric tracking, with no labeling, to avoid waste of labels; 7. The main materials of the equipment are stainless steel and high-grade aluminum alloy, the overall structure is firm, beautiful and generous; 8. With fault shutdown function, production counting function, power saving function, production number setting shutdown function, parameter setting protection function, convenient production management; 10. Optional functions and components: hot coding/coding, automatic feeding, automatic receiving, additional labeling device, other labeling device (customized according to customer requirements).

Machine Details

Our samples

Company Information

-

CNC Glass Bottle Printer

-

Automatic Bottle Machine LINE

-

Cup/ Tube/ Lipstick/SyringPrinting LINE

-

Hot Stamping Machine

-

Heat Transfer Machine

-

Servo Motor Screen Printing Machine

-

UV Curing Machine

-

Cylinder Screen Printing Machine

-

IR Hot Drying Tunnel

-

Flat Bed Screen Printer

-

Special Pad Printer

-

Packaging Machines

-

Labeling Machine